Yacht is no longer available for sale.

Yacht is no longer available for sale.

This is an archived web page showing historic information for reference purposes only. Search Yachts for Sale.

Yacht is no longer available for sale.

This is an archived web page showing historic information for reference purposes only. Search Yachts for Sale.

Not for sale or charter to U.S. residents while in U.S. waters.

| Builder | Nautor's Swan |

|---|---|

| Model | 66 |

| Length (LOA) | 66' (20.12m) |

| Year | 2008 |

| Draft | 10' 5" (3.18m) |

| Beam | 17' 7" (5.36m) |

| Location | Cayman Islands |

| Staterooms | 4 |

|---|---|

| Sleeps | 10 |

| Heads | 3 |

| Capt. Quarters | No |

|---|

| LOA | 66' (20.12m) |

|---|---|

| LWL | 57' (17.17m) |

| Max Draft | 10' 5" (3.18m) |

| Fuel Tank | 343 g (1,300 L) |

| Fresh Water | 132 g (500 L) |

| Displacement | 66,000 |

| Hull Material | Fiberglass |

|---|---|

| Stabilizers | None |

Complete the form below and one of our experienced sales brokers will be in touch soon.

HULL & APPENDAGES

Construction

Scantlings, materials and workmanship throughout are consistent with the construction of a light hull, but without any sacrifice of the strength or stiffness. The hull is built in a female mould using vacuum assisted resin infusion. The bottom is of single skin construction, the topsides of foam cored sandwich, using glass/aramid hybrid fibre reinforced vinylester laminate. A high proportion of the fibres are unidirectional, giving a stiff laminate with excellent strength and fatigue properties.

Structural bulkheads are manufactured by using vacuum assisted resin infusion, and of foam cored sandwich with carbon fibre skins, and laminated to hull and deck. Stiffener flanges are unidirectional carbon lay-ups over foam cores or hollow double bias glass formers.Engine beds are of GRP with steel inserts; special care is taken to assure rigid foundation and proper adhesion to the hullComposite main shroud chain plates bonded to hull and to reinforced structural knees.Recessed stainless steel headstay chainplate and deck level composite backstay chain plates attached to hull structure.

Finish

Gelcoats are of weather resistant NGA type.

Topside colour is white, boot top, cove stripe and coaming stripe in grey alwgrip paint

Uncoloured gelcoat below waterline.

Bottom treated with epoxy primer for improved blistering resistance and antifouled.

Keel

The keel is lead casting alloyed with antimony and bolted to a bottom grid.

Keel bolts are of high-tensile stainless steel.

Steering Systems

Dual steering gear, sheaves provided with guards to prevent jamming.

Lightweight steering quadrant bolted to rudder stock.

2 x 1.20m destroyer type stainless steel wheels; 2.0 turns H.O. to H.O.

Pedestals with roller bearings and friction brake.

Emergency tiller stowed in lazarette.

Transom

Hydraulically controlled transom door/bathing platform with teak surface.

DECK

Deck Construction

Scantlings, materials and workmanship throughout are consistent with the construction of a light deck, but without the sacrifice of strength or stiffness. Main deck is of carbon fibre sandwich with foam core and manufactured by using vacuum assisted resin infusion, and bonded to the hull. High-density core under deck fittings. Coachroof and cockpit of glassfibre reinforced vinylester with foam core.

Laid teak 9mm nominal thickness on side and bridge decks, coachroof, cockpit sole and seats, glued and vacuum bagged without screws.

The lazarette is separated with a watertight bulkhead from the interior; in lazarette stowage for an inflatable.

Anchor locker with water tight collision bulkhead aft and rails for hanging sheets etc and spinnaker storage.

Deck Equipment

Pulpit, pushpit and lifeline stanchions 640mm high of stainless steel with composite bases; spacing conforming to ORC requirements, pulpit of the open type. Stainless steel life lines.

Gates in lifelines each side amidships.

Radar antenna on post at stern

Deck shower starboard side aft in lazarette

Roller fairleads integrated in pulpit bases forward and in pushpit bases aft

2 x Removable teak footrests for helmsman.

Hatches and Windows

On the foredeck, hinged hatches to deck stowage and anchor windlass.

Flush hinged sail hatch and openable deck hatches of composite construction.

Main companionway lockable sliding hatch of tined acrylic with sliding dropboard plus aft companion

Hinged Hatch to lazarette in cockpit

Winches

Winches are Harken self-tailing electric powered.

2 x Primary B980.3 STE 2-speed.

2 x Secondary/mainsheet B980.3 STE 2-speed.

2 x Halyard B60.2 STE 2-speed coachroof.

2 x Manual runner

2 x 10” lock-in

2 x 10” double-grip winch handles.

Sailing Hardware

Harken deck gear.

1 x Pair of cars with stoppers for jib sheets.

Roller bearing lead blocks for halyards and slab reefing at mast partners.

Aluminium jib sheet T-tracks with cars.

Lead block for jib sheets.

Mainsheet single point deck attachment on coachroof, double ended sheet led forward along boom to gooseneck, down to deck, and aft to cockpit below deck.

INTERIOR

Carefully selected light teak is varnished and hand rubbed to give a satin finish for all visible woodwork. Removable overhead panels are installed in all accommodation areas and finished in white vinyl.

All floorboards are lightweight PVC sandwich construction with grooved oak veneer. They are treated with several coats of hard wearing two-pack satin varnish and mounted on vibration damping material. Suction lifters are provided for each cabin.Interior bulkheads and panels are foam cored sandwich construction with teak veneers on marine ply skins. All partitions are built to meet 20dB (A) level of airborne noise reduction. Locker doors are fitted with high quality hinges and latches and hanging lockers are fitted with rails, hooks and automatic internal lights.

General cabin lighting is spotlight down lighting with dimmer controls for the main saloon. Reading lights are installed at the head of every berth, nav station and crew cabin desk. Red night lights are installed in main saloon and galley, and an additional one with on/off switch installed in the aft cabin. Nav station and crew cabin desk lights are dual white/red. An oilskin locker with ventilation and driptray is installed aft of the nav station in the aft passageway.

All drawers are made of teak with top quality latches. Mirrors are marine quality with sealed edges. Companionway ladders have non-slip steps and are supplied with padded heavy duty covers for heavy use. All berths have white canvas leecloths secured to stainless fittings in bulkheads and bed frame.

Mattresses for fixed berths are sprung type manufactured for marine use from fire retardant material and include foam cover mattresses. Bases are Deltaflex type batten system providing underside ventilation. Pullman berths have fire retardant foam mattresses. All mattresses and cover mattresses are finished in Annala Calico No.18 (cream) with piping in Annala Calico No.35 (beige) and are supplied with quilted fitted mattress covers.

Bathrooms/heads have white GRP countertops with Corian basins and soap dispensers. Shower stalls are white GRP with teak floor grating and white shower curtains where specified.

Heads & Showers

Equipped with Corian Glacier White washbasin, mirror, telephone type shower, towel, soap and paper holder, and lockers.

Full height GRP lining.

Single lever mixing faucets type Oras for wash basins, galley sinks and showers.

Galley sinks drain through seacocks.

Wash basins and showers drain to sump tanks, capacity of 7 litres (6.8 US pint) each. Sump tanks are emptied by electrical or manual whale pumps; outlets above waterline.

2 x Electrical toilets plus 1 x manual, using fresh water for flushing, and discharging to holding tanks with indication at 3/4 and 1/1 level; holding tanks emptied by electric pump or deck suction line.

Forward Cabin

Double berth port side with Pullman above.

Hanging locker and storage starboard.

Guest Cabins

Port cabin with double berth and Pullman above, hanging locker, and head with separate shower stall.

Starboard cabin with upper and lower berth, hanging locker, and head/shower doubling as a day head

Master Cabin

Double berth to port with drawers below.

Hanging locker.

Small sofa which can act as a sea berth.

Aft companionway access to rear cockpit.

Heads compartment with 'telephone' shower.

Extra large oilskin locker in passageway with blower/heater

Saloon

L-settee with dining table and bench port side (leather upholstery).

L-settee with coffee table starboard (leather upholstery).

Outboard lockers, bookshelves.

Separate wine and spirits lockers.

Galley

Insulated and sheathed space for stove with extractor hood over.

Corian countertops.Crockery locker on centreline above sink.

Chest of drawers for utensils.Teak bread board and chopping board.

Stowage under floorboards.Large garbage locker beside sink.

Large pan drawer under refrigerators

Galley Equipment

Stainless steel sinks.

Iceberg refrigeration unit with hold-over plates for refrigerator and freezer, 2 x 230v AC-driven 0.5hp units.

Stainless steel four-burner Force 10 gas stove with oven, gimballed and provided with fiddles; flame failure protection on burners.

Manual gas shut-off cock adjacent to stove.

Remote controlled shut-off and leak detector near gas bottle with control switch, warning light in galley and manual bypass.

Gas installation according to ISO 10239.

Quooker ST water boiler unit 800w 240v 3 litre (6.34 US pint) capacity.

Nav Station

Provided with shelves, lockers, drawers and space for instruments and radios on angled panels

Engine Room

Engine space internally sound insulated; fire resistance meeting SOLAS B-15 requirements.

ENGINE & SYSTEMS

Steyr 166hp. 120 kw engine with inline generator. Engine hours approx 2800 as at Nov 2019.

Propeller area sound insulated. Propeller shaft made of high-tensile corrosion resistant steel with flexible shaft couple. Drip-free shaft seal.

Shaft supported by rubber bearing at bracket and stern tube.

670mm three-bladed folding propeller, plus weed-cutter

Lubricating oil change pump, 24v, connected to both main engine, generator and gearbox.

Main engine cooling water is discharged with exhaust gases through transom; silencers provided with drain tap. Thermostat-controlled water cooling with heat exchanger on engine; seawater intake with strainer; discharge through exhaust system.

Engine cockpit controls:

·Engine control on/off.

·Start and stop buttons.

·Single lever control of throttle and gear shift.

·Coolant temperature gauge.

·Oil pressure gauge for engine.

·Tachometer with hour meter.

·Warning light and audible alarm for low oil pressure/high coolant or exhaust temperature.

·Control light for starting and service battery charging

Bow Thruster – Azimuth thruster

Plumbing Systems

Seafresh H2016D (S), 24volt pure DC. Output 250 l/hour (66 USG), including auto fresh water flush

The consumable water can be heated either with engine cooling water or by an AC powered water heater

Pressurized and heated water; total hot water capacity of 80 litres (21 USG).

Sea cocks of bronze for all through-hull connections below waterline outside engine space, closing flush with outside and located in accessible positions.

Sea water hoses of reinforced PVC tubing, fresh water piping of nylon and copper tubing

Ventilation System

Natural ventilation in cabins.

Exhaust ventilators in heads and galley.

Air inlet with water and sound trap, outlet with blowers in engine space.

Separate outlet for diesel generator cooling air with blower.

Battery boxes ventilated to outside.

Galley extractor hood fan.

Air conditioning with reversed cycle, Webasto blue cool premium 50,000 BTU/ 14.6kW, 230v with 2 x rotary compressors.

External heating unit Webasto Thermo 90 ST, 24v/9.1kW; with blowers and local controls in cabins, galley and saloon. Includes separate shore power inlet and cable.

Drainage System

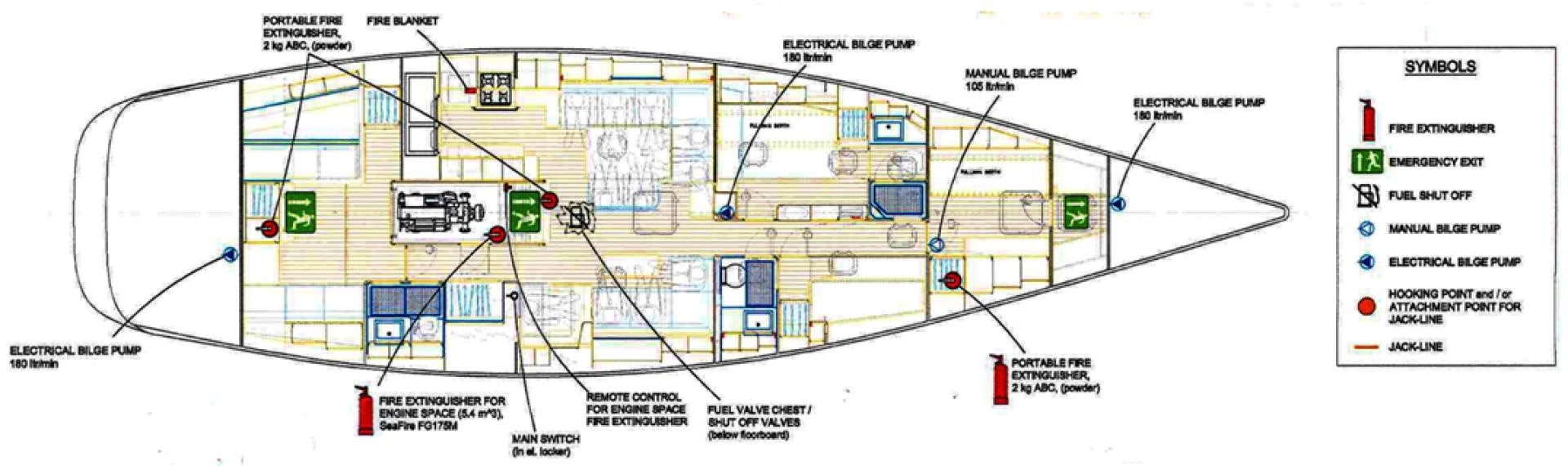

5 x Bilge pumps

3 x Electrical submersible pump with automatic switch 150ltr/min (39 USG)

2 x Hand pumps Whale Titan 100 ltr/min (26 USG)

Outlets above waterline

Chain locker/forepeak manual pump.

ELECTRICAL SYSTEM

DC System

Maintenance-free traction gelcell type for general service, AGM forstarting

Battery sets are located in ventilated GRP boxes

Service battery, gel cell; 24v 720Ah (20h), new 2017

Instrumentation battery, gel cell; 24v 290ah (20h), new 2018

Starting battery, AGM; 12v 75Ah (20h), new 2018

The engine and diesel generator have their own starting battery sets

AC System

The AC system can be fed either by the diesel generator, shore power or the inverter

Connection to battery charger, refrigeration and water heater resistor

Outlets provided with earth fault protection

12/24v outlet in cockpit

12/24v outlet on mast

Generator

10.2kW Panda 230v AC diesel generator with sound shield. Gen set hours approx 600 as at Nov 2019

Two-stage silencing exhaust system with fiberglass silencer and gas/water separator for diesel generator.

Generator cooling water is discharged below waterline; silencers provided with drain tap

Shore Power

Shore power connection; 230v 50a 50Hz; provided with polarity alarm, main switch and land connecting cable. Additional 230V shore power inlet including isolation transformer 7kVA 230V out for USA and Caribbean

Chargers/Inverters

The service batteries are charged by a 140a alternator on the main engine or by a two Mass 24/75amp battery chargers working on AC

The main engine starting batteries are charged by a 55a alternator on the main engine, new 2019

The diesel generator starting battery is charged by a 35a alternator on the genset

Mass Sine 24/2500 VA 230v inverter with transfer switch

ELECTRONIC SYSTEMS

Navigation Instruments

Suunto 135mm magnetic compasses on steering pedestals.

Wempe Quartz clock and barometer in saloon.

B & G Hercules sailing instruments

Raymarine E120 radar/plotter with E80 repeater at the helm.

Leica MX420/2 GPS.

Autopilot System

B & G H3000 Hydra autopilot, with alternate back-up control system.

Hydraulic autopilot B&G Hydra driving the steering quadrant with control panel in cockpit., New 2017

Computer Systems

PC computer and screen

Communications Systems

SeaMe radar target enhancer.

ICOM 505 VHF with mike at helm.

Iridium SC4000 voice/data.

Comar CSB 200 AIS.

Navtex ICS Navplus.

Entertainment Systems

Sony GT310 stereo radio players in saloon and in owner’s cabin.

MAST & RIGGING

The carbon mast is stepped through the deck onto a composite mast step

Recessed Reckmann hydraulic headsail furler

Spars are built of standard modulus carbon fibre and painted white

Three spreader rig with discontinuous shrouds and swept spreaders, built by reputable mast builder

Inner forestay (detached) and runners of aramid

Inner forestay rod with hydraulic Reckmann furler

Park avenue type boom with hydraulic outhaul and arranged for single line reefing with 2 x reefing lines

Carbon spinnaker pole on mast

Lazy jacks

Reaching strut in carbon stowed on side deck

Hydraulic mast jack with spacer and removable manual pump

Furler for staysail led to halyard winch in forward cockpit

Navtec manual hydraulic rig controls:

·Boom Vang

·Backstay

·Outhaul

·Jib Halyard

Sailplan

IG: 90’2” / 27.50m

J: 24’5” / 7.45m

P: 82’10” / 25.25m

E: 24’11” / 7.60m

Fore Triangle: 1102.6 sq.ft / 102.4m2.

Main Sail: 1308.9 sq.ft / 121.6m2.

Jib: 1026.9 sq.ft / 95.4m2.

SAILS

|

Sail |

Year |

Sailmaker |

Material/Notes |

|

MAINSAILS |

HULL & APPENDAGES

Construction

Scantlings, materials and workmanship throughout are consistent with the construction of a light hull, but without any sacrifice of the strength or stiffness. The hull is built in a female mould using vacuum assisted resin infusion. The bottom is of single skin construction, the topsides of foam cored sandwich, using glass/aramid hybrid fibre reinforced vinylester laminate. A high proportion of the fibres are unidirectional, giving a stiff laminate with excellent strength and fatigue properties.

Structural bulkheads are manufactured by using vacuum assisted resin infusion, and of foam cored sandwich with carbon fibre skins, and laminated to hull and deck. Stiffener flanges are unidirectional carbon lay-ups over foam cores or hollow double bias glass formers.Engine beds are of GRP with steel inserts; special care is taken to assure rigid foundation and proper adhesion to the hullComposite main shroud chain plates bonded to hull and to reinforced structural knees.Recessed stainless steel headstay chainplate and deck level composite backstay chain plates attached to hull structure.

Finish

Gelcoats are of weather resistant NGA type.

Topside colour is white, boot top, cove stripe and coaming stripe in grey alwgrip paint

Uncoloured gelcoat below waterline.

Bottom treated with epoxy primer for improved blistering resistance and antifouled.

Keel

The keel is lead casting alloyed with antimony and bolted to a bottom grid.

Keel bolts are of high-tensile stainless steel.

Steering Systems

Dual steering gear, sheaves provided with guards to prevent jamming.

Lightweight steering quadrant bolted to rudder stock.

2 x 1.20m destroyer type stainless steel wheels; 2.0 turns H.O. to H.O.

Pedestals with roller bearings and friction brake.

Emergency tiller stowed in lazarette.

Transom

Hydraulically controlled transom door/bathing platform with teak surface.

DECK

Deck Construction

Scantlings, materials and workmanship throughout are consistent with the construction of a light deck, but without the sacrifice of strength or stiffness. Main deck is of carbon fibre sandwich with foam core and manufactured by using vacuum assisted resin infusion, and bonded to the hull. High-density core under deck fittings. Coachroof and cockpit of glassfibre reinforced vinylester with foam core.

Laid teak 9mm nominal thickness on side and bridge decks, coachroof, cockpit sole and seats, glued and vacuum bagged without screws.

The lazarette is separated with a watertight bulkhead from the interior; in lazarette stowage for an inflatable.

Anchor locker with water tight collision bulkhead aft and rails for hanging sheets etc and spinnaker storage.

Deck Equipment

Pulpit, pushpit and lifeline stanchions 640mm high of stainless steel with composite bases; spacing conforming to ORC requirements, pulpit of the open type. Stainless steel life lines.

Gates in lifelines each side amidships.

Radar antenna on post at stern

Deck shower starboard side aft in lazarette

Roller fairleads integrated in pulpit bases forward and in pushpit bases aft

2 x Removable teak footrests for helmsman.

Hatches and Windows

On the foredeck, hinged hatches to deck stowage and anchor windlass.

Flush hinged sail hatch and openable deck hatches of composite construction.

Main companionway lockable sliding hatch of tined acrylic with sliding dropboard plus aft companion

Hinged Hatch to lazarette in cockpit

Winches

Winches are Harken self-tailing electric powered.

2 x Primary B980.3 STE 2-speed.

2 x Secondary/mainsheet B980.3 STE 2-speed.

2 x Halyard B60.2 STE 2-speed coachroof.

2 x Manual runner

2 x 10” lock-in

2 x 10” double-grip winch handles.

Sailing Hardware

Harken deck gear.

1 x Pair of cars with stoppers for jib sheets.

Roller bearing lead blocks for halyards and slab reefing at mast partners.

Aluminium jib sheet T-tracks with cars.

Lead block for jib sheets.

Mainsheet single point deck attachment on coachroof, double ended sheet led forward along boom to gooseneck, down to deck, and aft to cockpit below deck.

INTERIOR

Carefully selected light teak is varnished and hand rubbed to give a satin finish for all visible woodwork. Removable overhead panels are installed in all accommodation areas and finished in white vinyl.

All floorboards are lightweight PVC sandwich construction with grooved oak veneer. They are treated with several coats of hard wearing two-pack satin varnish and mounted on vibration damping material. Suction lifters are provided for each cabin.Interior bulkheads and panels are foam cored sandwich construction with teak veneers on marine ply skins. All partitions are built to meet 20dB (A) level of airborne noise reduction. Locker doors are fitted with high quality hinges and latches and hanging lockers are fitted with rails, hooks and automatic internal lights.

General cabin lighting is spotlight down lighting with dimmer controls for the main saloon. Reading lights are installed at the head of every berth, nav station and crew cabin desk. Red night lights are installed in main saloon and galley, and an additional one with on/off switch installed in the aft cabin. Nav station and crew cabin desk lights are dual white/red. An oilskin locker with ventilation and driptray is installed aft of the nav station in the aft passageway.

All drawers are made of teak with top quality latches. Mirrors are marine quality with sealed edges. Companionway ladders have non-slip steps and are supplied with padded heavy duty covers for heavy use. All berths have white canvas leecloths secured to stainless fittings in bulkheads and bed frame.

Mattresses for fixed berths are sprung type manufactured for marine use from fire retardant material and include foam cover mattresses. Bases are Deltaflex type batten system providing underside ventilation. Pullman berths have fire retardant foam mattresses. All mattresses and cover mattresses are finished in Annala Calico No.18 (cream) with piping in Annala Calico No.35 (beige) and are supplied with quilted fitted mattress covers.

Bathrooms/heads have white GRP countertops with Corian basins and soap dispensers. Shower stalls are white GRP with teak floor grating and white shower curtains where specified.

Heads & Showers

Equipped with Corian Glacier White washbasin, mirror, telephone type shower, towel, soap and paper holder, and lockers.

Full height GRP lining.

Single lever mixing faucets type Oras for wash basins, galley sinks and showers.

Galley sinks drain through seacocks.

Wash basins and showers drain to sump tanks, capacity of 7 litres (6.8 US pint) each. Sump tanks are emptied by electrical or manual whale pumps; outlets above waterline.

2 x Electrical toilets plus 1 x manual, using fresh water for flushing, and discharging to holding tanks with indication at 3/4 and 1/1 level; holding tanks emptied by electric pump or deck suction line.

Forward Cabin

Double berth port side with Pullman above.

Hanging locker and storage starboard.

Guest Cabins

Port cabin with double berth and Pullman above, hanging locker, and head with separate shower stall.

Starboard cabin with upper and lower berth, hanging locker, and head/shower doubling as a day head

Master Cabin

Double berth to port with drawers below.

Hanging locker.

Small sofa which can act as a sea berth.

Aft companionway access to rear cockpit.

Heads compartment with 'telephone' shower.

Extra large oilskin locker in passageway with blower/heater

Saloon

L-settee with dining table and bench port side (leather upholstery).

L-settee with coffee table starboard (leather upholstery).

Outboard lockers, bookshelves.

Separate wine and spirits lockers.

Galley

Insulated and sheathed space for stove with extractor hood over.

Corian countertops.Crockery locker on centreline above sink.

Chest of drawers for utensils.Teak bread board and chopping board.

Stowage under floorboards.Large garbage locker beside sink.

Large pan drawer under refrigerators

Galley Equipment

Stainless steel sinks.

Iceberg refrigeration unit with hold-over plates for refrigerator and freezer, 2 x 230v AC-driven 0.5hp units.

Stainless steel four-burner Force 10 gas stove with oven, gimballed and provided with fiddles; flame failure protection on burners.

Manual gas shut-off cock adjacent to stove.

Remote controlled shut-off and leak detector near gas bottle with control switch, warning light in galley and manual bypass.

Gas installation according to ISO 10239.

Quooker ST water boiler unit 800w 240v 3 litre (6.34 US pint) capacity.

Nav Station

Provided with shelves, lockers, drawers and space for instruments and radios on angled panels

Engine Room

Engine space internally sound insulated; fire resistance meeting SOLAS B-15 requirements.

ENGINE & SYSTEMS

Steyr 166hp. 120 kw engine with inline generator. Engine hours approx 2800 as at Nov 2019.

Propeller area sound insulated. Propeller shaft made of high-tensile corrosion resistant steel with flexible shaft couple. Drip-free shaft seal.

Shaft supported by rubber bearing at bracket and stern tube.

670mm three-bladed folding propeller, plus weed-cutter

Lubricating oil change pump, 24v, connected to both main engine, generator and gearbox.

Main engine cooling water is discharged with exhaust gases through transom; silencers provided with drain tap. Thermostat-controlled water cooling with heat exchanger on engine; seawater intake with strainer; discharge through exhaust system.

Engine cockpit controls:

·Engine control on/off.

·Start and stop buttons.

·Single lever control of throttle and gear shift.

·Coolant temperature gauge.

·Oil pressure gauge for engine.

·Tachometer with hour meter.

·Warning light and audible alarm for low oil pressure/high coolant or exhaust temperature.

·Control light for starting and service battery charging

Bow Thruster – Azimuth thruster

Plumbing Systems

Seafresh H2016D (S), 24volt pure DC. Output 250 l/hour (66 USG), including auto fresh water flush

The consumable water can be heated either with engine cooling water or by an AC powered water heater

Pressurized and heated water; total hot water capacity of 80 litres (21 USG).

Sea cocks of bronze for all through-hull connections below waterline outside engine space, closing flush with outside and located in accessible positions.

Sea water hoses of reinforced PVC tubing, fresh water piping of nylon and copper tubing

Ventilation System

Natural ventilation in cabins.

Exhaust ventilators in heads and galley.

Air inlet with water and sound trap, outlet with blowers in engine space.

Separate outlet for diesel generator cooling air with blower.

Battery boxes ventilated to outside.

Galley extractor hood fan.

Air conditioning with reversed cycle, Webasto blue cool premium 50,000 BTU/ 14.6kW, 230v with 2 x rotary compressors.

External heating unit Webasto Thermo 90 ST, 24v/9.1kW; with blowers and local controls in cabins, galley and saloon. Includes separate shore power inlet and cable.

Drainage System

5 x Bilge pumps

3 x Electrical submersible pump with automatic switch 150ltr/min (39 USG)

2 x Hand pumps Whale Titan 100 ltr/min (26 USG)

Outlets above waterline

Chain locker/forepeak manual pump.

ELECTRICAL SYSTEM

DC System

Maintenance-free traction gelcell type for general service, AGM forstarting

Battery sets are located in ventilated GRP boxes

Service battery, gel cell; 24v 720Ah (20h), new 2017

Instrumentation battery, gel cell; 24v 290ah (20h), new 2018

Starting battery, AGM; 12v 75Ah (20h), new 2018

The engine and diesel generator have their own starting battery sets

AC System

The AC system can be fed either by the diesel generator, shore power or the inverter

Connection to battery charger, refrigeration and water heater resistor

Outlets provided with earth fault protection

12/24v outlet in cockpit

12/24v outlet on mast

Generator

10.2kW Panda 230v AC diesel generator with sound shield. Gen set hours approx 600 as at Nov 2019

Two-stage silencing exhaust system with fiberglass silencer and gas/water separator for diesel generator.

Generator cooling water is discharged below waterline; silencers provided with drain tap

Shore Power

Shore power connection; 230v 50a 50Hz; provided with polarity alarm, main switch and land connecting cable. Additional 230V shore power inlet including isolation transformer 7kVA 230V out for USA and Caribbean

Chargers/Inverters

The service batteries are charged by a 140a alternator on the main engine or by a two Mass 24/75amp battery chargers working on AC

The main engine starting batteries are charged by a 55a alternator on the main engine, new 2019

The diesel generator starting battery is charged by a 35a alternator on the genset

Mass Sine 24/2500 VA 230v inverter with transfer switch

ELECTRONIC SYSTEMS

Navigation Instruments

Suunto 135mm magnetic compasses on steering pedestals.

Wempe Quartz clock and barometer in saloon.

B & G Hercules sailing instruments

Raymarine E120 radar/plotter with E80 repeater at the helm.

Leica MX420/2 GPS.

Autopilot System

B & G H3000 Hydra autopilot, with alternate back-up control system.

Hydraulic autopilot B&G Hydra driving the steering quadrant with control panel in cockpit., New 2017

Computer Systems

PC computer and screen

Communications Systems

SeaMe radar target enhancer.

ICOM 505 VHF with mike at helm.

Iridium SC4000 voice/data.

Comar CSB 200 AIS.

Navtex ICS Navplus.

Entertainment Systems

Sony GT310 stereo radio players in saloon and in owner’s cabin.

MAST & RIGGING

The carbon mast is stepped through the deck onto a composite mast step

Recessed Reckmann hydraulic headsail furler

Spars are built of standard modulus carbon fibre and painted white

Three spreader rig with discontinuous shrouds and swept spreaders, built by reputable mast builder

Inner forestay (detached) and runners of aramid

Inner forestay rod with hydraulic Reckmann furler

Park avenue type boom with hydraulic outhaul and arranged for single line reefing with 2 x reefing lines

Carbon spinnaker pole on mast

Lazy jacks

Reaching strut in carbon stowed on side deck

Hydraulic mast jack with spacer and removable manual pump

Furler for staysail led to halyard winch in forward cockpit

Navtec manual hydraulic rig controls:

·Boom Vang

·Backstay

·Outhaul

·Jib Halyard

Sailplan

IG: 90’2” / 27.50m

J: 24’5” / 7.45m

P: 82’10” / 25.25m

E: 24’11” / 7.60m

Fore Triangle: 1102.6 sq.ft / 102.4m2.

Main Sail: 1308.9 sq.ft / 121.6m2.

Jib: 1026.9 sq.ft / 95.4m2.

SAILS

|

Sail |

Year |

Sailmaker |

Material/Notes |

|

MAINSAILS |

Complete the form below and one of our experienced sales brokers will be in touch soon.