Yacht is no longer available for sale.

Yacht is no longer available for sale.

This is an archived web page showing historic information for reference purposes only. Search Yachts for Sale.

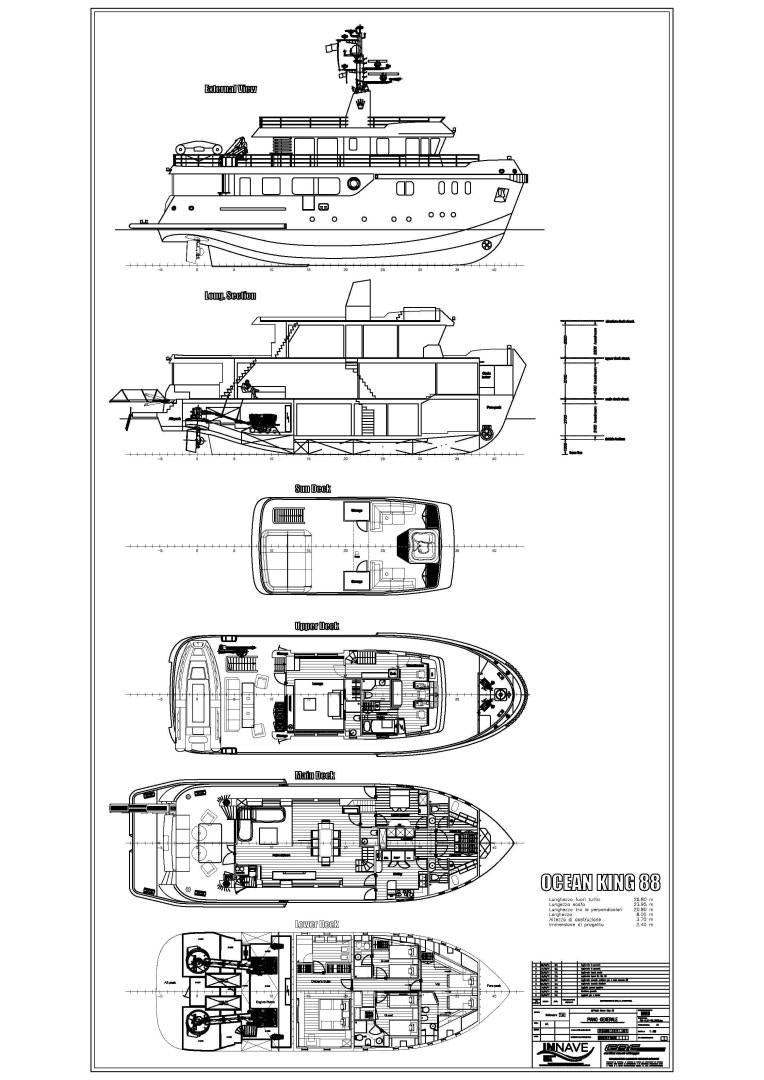

The Ocean King 88 is built on the base frame of a true ocean going tug. It has the same hull structure and base systems found in the tugs with changes to make her better suited to yacht use than you can find in a converted tug. She has 2475 sq ft of interior living space making her a true home on the water. The exterior space is 2690 sq ft , combined it is 5165 sq ft, which is much larger then her closest competitors.

Northrop and Johnson is pleased to assist you in the purchase of this vessel. This boat is centrally listed by All Ocean Yachts. It is offered as a convenience by this broker/dealer to its clients and is not intended to convey direct representation of a particular vessel

| Builder | Ocean King |

|---|---|

| Model | 88 |

| Length (LOA) | 88' 6" (26.97m) |

| Year | 2023 |

| Draft | 8' 2" (2.49m) |

| Beam | 26' 2" (7.98m) |

| Range | 5,000 NM |

| Location | Chioggia, Italy |

| Staterooms | 5 |

|---|---|

| Heads | 5 |

| Capt. Quarters | No |

|---|

| LOA | 88' 6" (26.97m) |

|---|---|

| LOD | 79' (24.05m) |

| Min Draft | 7' 6" (2.29m) |

| Max Draft | 8' 2" (2.49m) |

| Fuel Tank | 10,450 g |

| Fresh Water | 2,930 g |

| Holding Tank | 400 g |

| Hull Material | Steel |

|---|---|

| Max Speed | 12 Knots |

| Cruising Speed | 10 Knots |

| Range | 5,000 NM |

| Stabilizers | None |

| Engine Make | MAN |

|---|---|

| Engine Model | D2842 LE412 |

| Engine Year | 2018 |

| Engine Type | Inboard |

| Power HP | 760 |

| Power KW | 567 |

| Fuel Type | Diesel |

Northrop and Johnson is pleased to assist you in the purchase of this vessel. This boat is centrally listed by All Ocean Yachts. It is offered as a convenience by this broker/dealer to its clients and is not intended to convey direct representation of a particular vessel

Complete the form below and one of our experienced sales brokers will be in touch soon.